Welcome to DICE by CWC

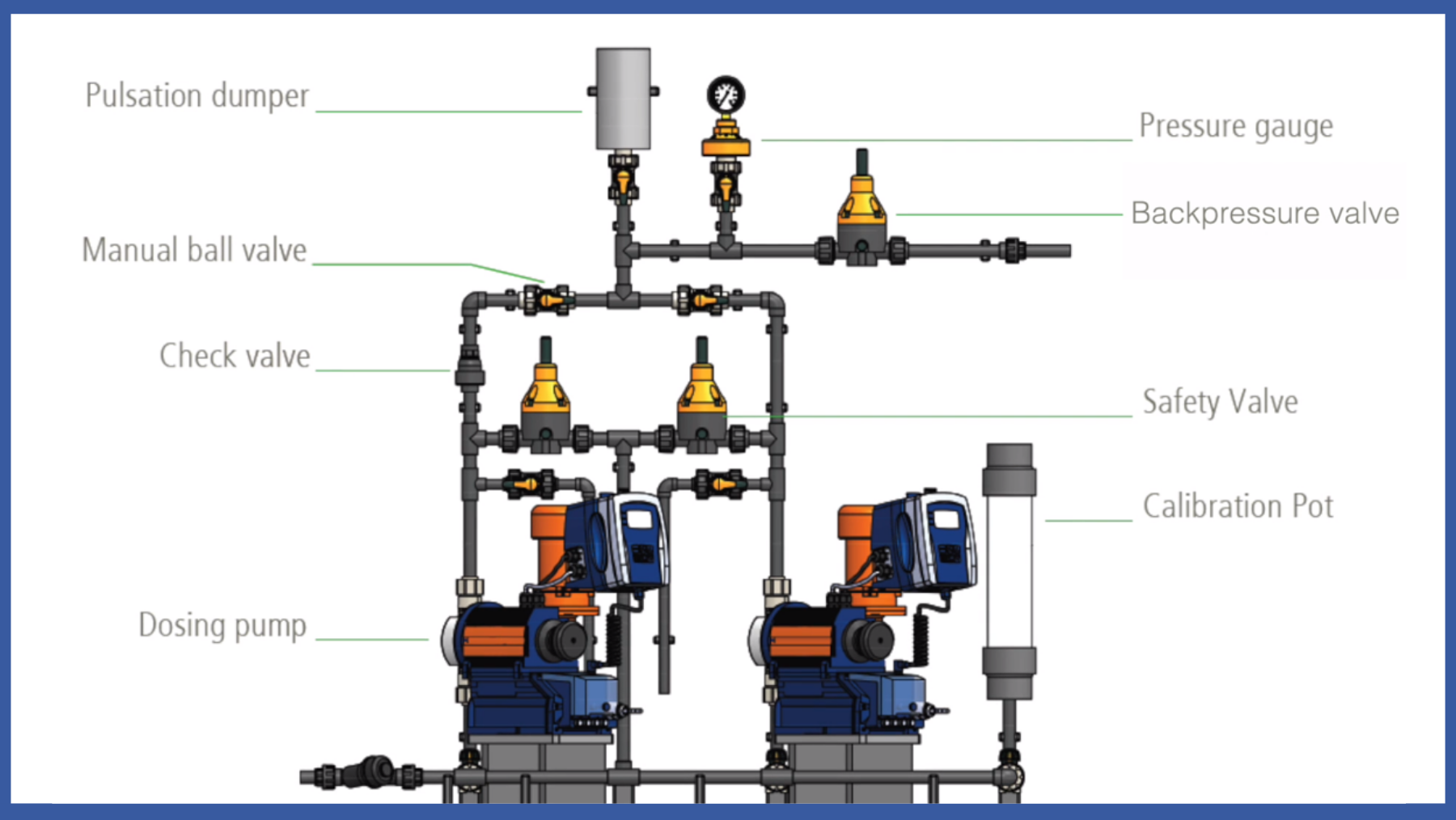

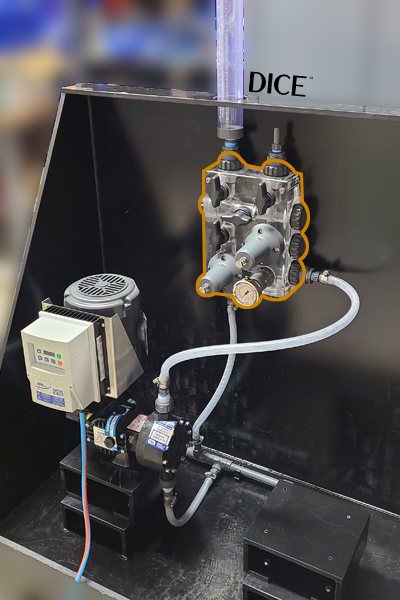

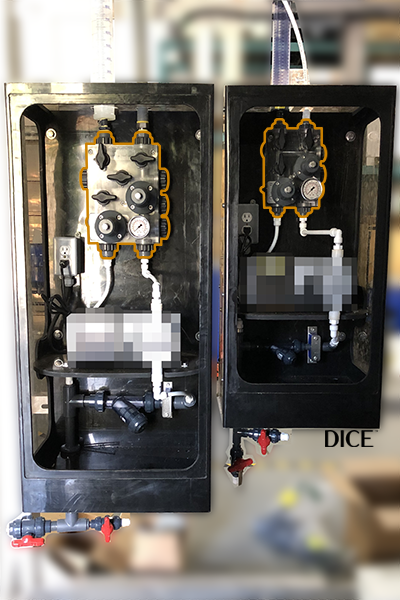

The DICE™ chemical dosing skid modules integrate all the necessary discharge components required for a typical chemical dosing system.

The block-type design ensures a compact, modular dosing skid that is rigid, reliable, and significantly reduces connections to minimize leakage potential.

These dosing modules provide superior precision and protection for chemical dosing, and their compact footprint makes them ideal for confined spaces, unlike traditional chemical dosing systems.

What's on this page?

Discrete components can be mounted and plumbed together to achieve the following for any chemical dosing skid:

- Calibration of dosing pump/s

- Chemical bypass back to chemical tank if overpressure

- Constant backpressure to achieve constant dosing

- Readout of manifold pressure

- Manual valving for setting each configuration.

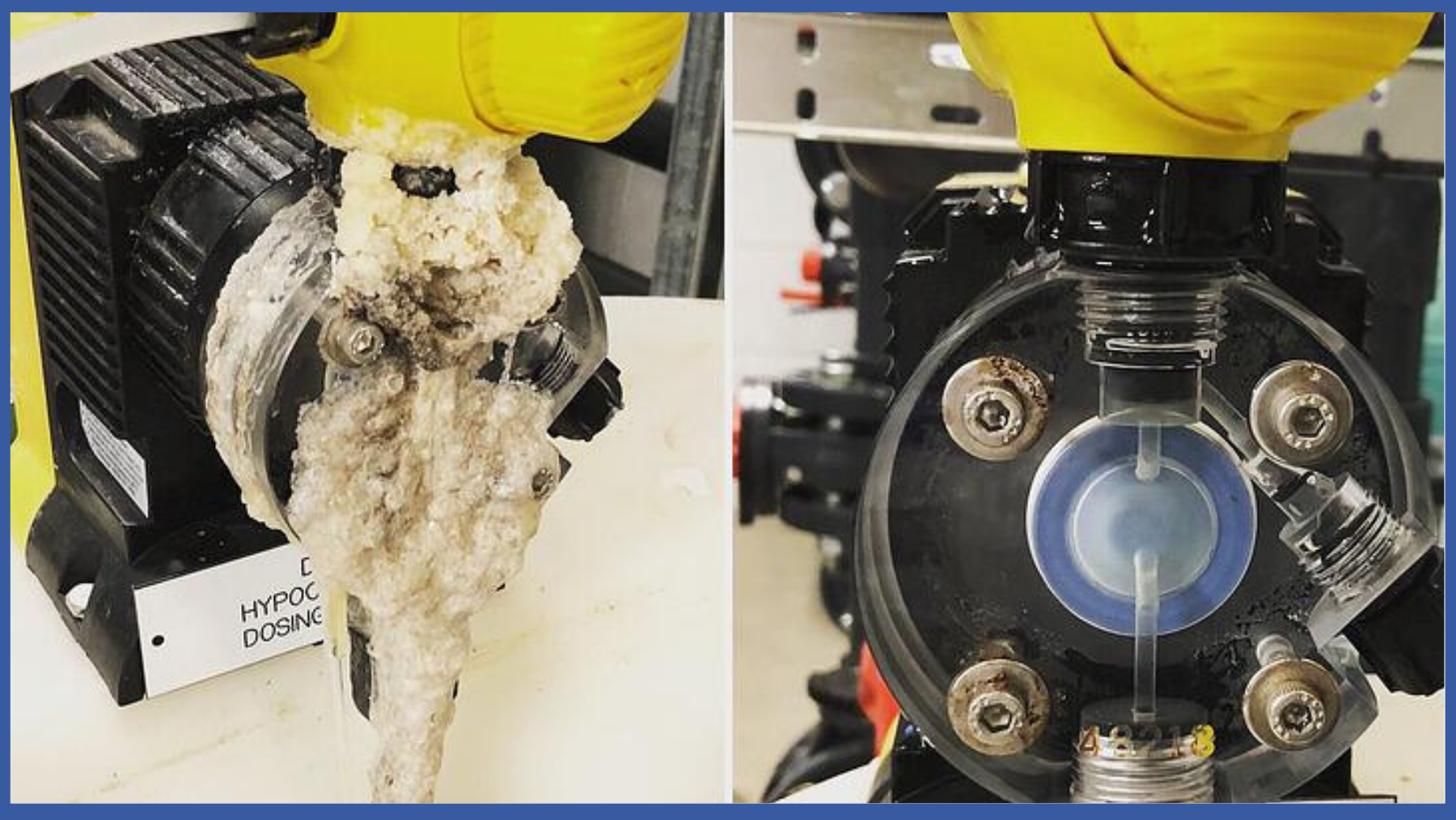

The Problems with Traditional Chemical Dosing Skids

- Large footprint

- Long time to fabricate

- Many solvent weld joints prone to leakages

- Many threaded joints prone to leakages

- Expensive to repair

- More expensive maintenance

Re-inventing Chemical Dosing Skids

Traditional Dosing Modules often experience:

-

Breakages

-

Chemical Leakages

-

Take Up Large Amounts of Space

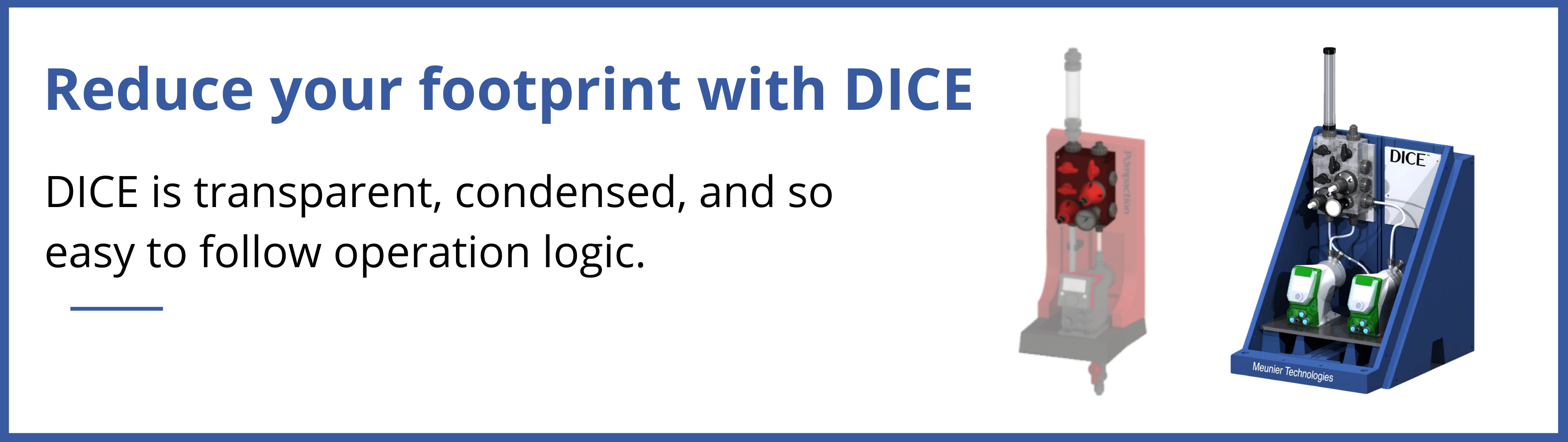

The DICE™ chemical dosing skid offers a compact solution, replacing traditional skids with an innovative, integrated modular dosing system that significantly reduces space requirements.

Why DICE Dosing Modules?

How DICE makes Chemical Dosing smarter, safer, simpler and more reliable:

- Compact

- Reliable

- Robust

- Transparent so you can see in what mode it is operating

- Pressure relief can be visually observed

- Low cost of maintenance

What Makes DICE modules Robust and Reliable?

-

No Solvent Weld Connections

-

No Thread Joints

-

Available Exclusively in Australia

DICE Componentry

1. Ball Valves

2. Pressure Relief Valve

3. Back Pressure Valve

4. Pressure Gauge with Isolator

Inventing DICE

Dice was invented to be a simple and reliable re-invention to traditional Chemical Dosing Systems.

The modules allow for better precision and protection in the dosing system. They also feature great quality due to their machined fabrication and an extremely small required footprint. DICE™ dosing modules integrate all the necessary discharge components.

Dice Applications Gallery

Recent DICE installations

< swipe with your finger or click and drag left or right >

Get your DICE products today!

Here's what we have available in stock, ex. stock Australia!

DM Flooded Suction Dosing Module

- Simple installation – 3 bolts and 4 connections

- Extremely high quality due to individual machined components.

- Overcomes issues of traditional piping systems such as bad joints, many potential leakage points and continual dosing pump pulsation causing mechanical fatigue.

- Optional Calibration column installs directly onto DICE

- Standard configuration: 1/2″, 150 psi max, Transparent Acrylic Body, PVC parts

- On request: 1″, 250 psi max, Block in PVC or PVDF

- O-ring options: Viton or EPDM

- Many port configurations available: Solvent Weld, NPT Female, BSP or NPT male for hose connection kit

- Possibility of having only 1 dosing module for 3 pumps

- Patented Design – Meunier Technologies

DS Suction Lift Dosing Module

- Simple installation – 3 bolts and 4 connections

- Extremely high quality due to individual machined components.

- Overcomes issues of traditional piping systems such as bad joints, many potential leakage points and continual dosing pump pulsation causing mechanical fatigue.

- Optional Calibration column installs directly onto DICE

- Standard configuration: 1/2″, 150 psi max, Transparent Acrylic Body, PVC parts

- On request: 1″, 250 psi max, Block in PVC or PVDF

- O-ring options: Viton or EPDM

- Many port configurations available: Solvent Weld, NPT Female, BSP or NPT male for hose connection kit

- Possibility of having only 1 dosing module for 3 pumps

- Patented Design – Meunier Technologies